- The stitch density of buttonholes must fully cover the edges and the button must pass through the buttonhole without stretching or breaking the stitching.

- Buttons must be firmly attached with backstitching or properly secured chain stitching.

- Buttons distance at placket is 8 cm for size 38 unless requested otherwise in style sketch.

- Buttons must be divided evenly and buttonholes position must be matched to buttons.

- Buttonholes size must match the button size correctly.

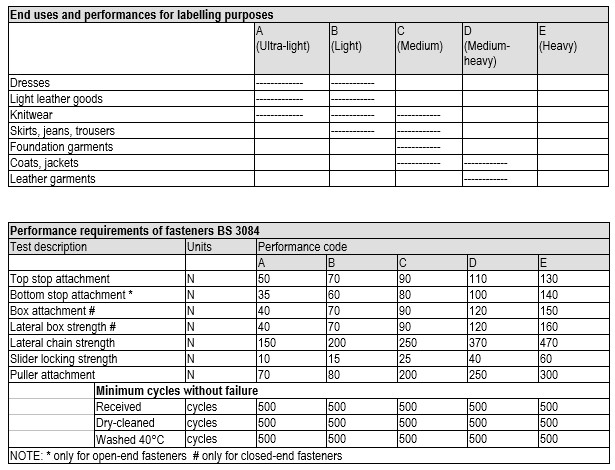

- Zippers of the following brands are accepted: YKK, YKK Vislon, YKK Zaglan, TIT, SAB, SBS, YBS, CMZ, Opti, Albert Zips (Gavotex). Brandless zippers are not allowed.

- Zippers must have the correct length and size, fitting for the size and type of garment.

- Zipper must be attached without tension on zipper or fabric to avoid puckering of the fabric.

- Zip fastenings must run smooth and flawless, with top and end stops.

- Zipper attachment must allow smooth and free running of the slider between fabrics.

- If a cut and sew seam is interrupted by a zipper, both sides must come out matching at the same height after the zipper is attached.

- All fasteners, press-studs, and decorative fastenings, including rings, buckles, zip fastenings, eyelets and Velcro must be strongly attached to the fabric. They must not have sharp edges and must work properly.

- Overlaps of fastenings must be sufficiently wide to avoid the lower placket to be visible.

- Inside buttons must be used in case of two-row fastenings, or if styling otherwise requires it.

- Women’s garments with front button closure must have a button positioned at bust height.

- Counter-buttons must be used for fabrics of a loose or open quality.

- Pin-buttons must be used for bulky fabrics.

- Hooks and eyes must be attached properly.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.